Casting simulation and prototyping

High-precision and efficient solutions with casting simulation and prototyping

Innovative casting simulation and prototyping for excellent product development

You too can rely on our advanced casting simulation and prototyping processes to turn your product ideas into reality. We not only offer you comprehensive advice and support in all project phases, but also state-of-the-art realisation of your ideas.

Casting simulation: perfecting the casting process

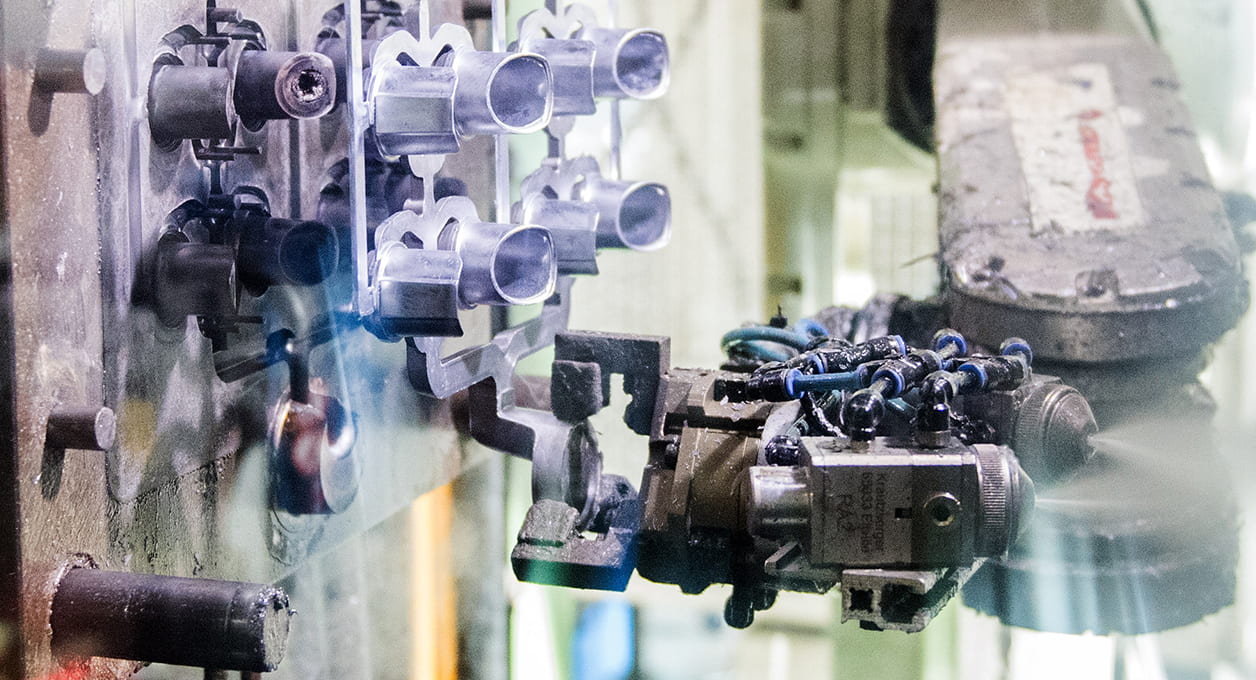

In casting simulation, we simulate and optimise the casting process before production starts. This mould and filling simulation of the tools enables us to reduce faults and minimise defects such as pores and blowholes. In this way, we ensure that the mould works in practice and that efficiency is guaranteed right from the start.

Why you should choose our expertise in casting simulation and prototyping

- Detailed inspection & optimisation of the casting process before the start of production.

- Reduction of errors & faults to maximise efficiency and quality.

- Comprehensive advice & support in all project phases.

Our services in precision die casting

From the idea to the ready-to-install component

Discover the precision of die casting with Sander!

Ready to take your projects to the next level? We offer customised precision solutions for your die casting requirements. Contact us today to find out more.

Questions and answers on Casting simulation and prototyping

The casting simulation includes a detailed mould and filling simulation of the tools before the start of production. It helps us to optimise the casting process and ensure that the tool works perfectly in practice. This allows us to increase efficiency and minimise errors in the process.

We turn your ideas into reality through prototyping. We use various processes such as die casting, investment casting, 3D printing and CNC to check the function, shape and design of your product and produce a prototype. This enables us to make adjustments at an early stage and perfect the end product.

We offer a wide range of prototyping options, including die casting, investment casting, 3D printing and CNC processes. These techniques enable us to respond quickly and flexibly to your specific requirements and create high-quality prototypes.

The combination of casting simulation and prototyping enables us to optimise the entire production process from the planning phase to the finished product. We can identify and eliminate potential sources of error at an early stage, which increases efficiency and ensures the quality of the end product.