Surface treatment

Precise refinement for a flawless finish.

Wide range of finishing techniques for surface treatment

Surface treatment plays a decisive role in giving die-cast parts not only an aesthetic but also a functional finish. From electroplating and powder coating to anodizing and painting, we offer a variety of finishing techniques. Our processes are designed to maximize the durability, functionality and appearance of your products.

Surface treatment: Benefits

- Comprehensive range of finishing techniques for individual requirements

- High-quality surfaces that combine protection and aesthetics

- State-of-the-art technologies for an even and durable finish

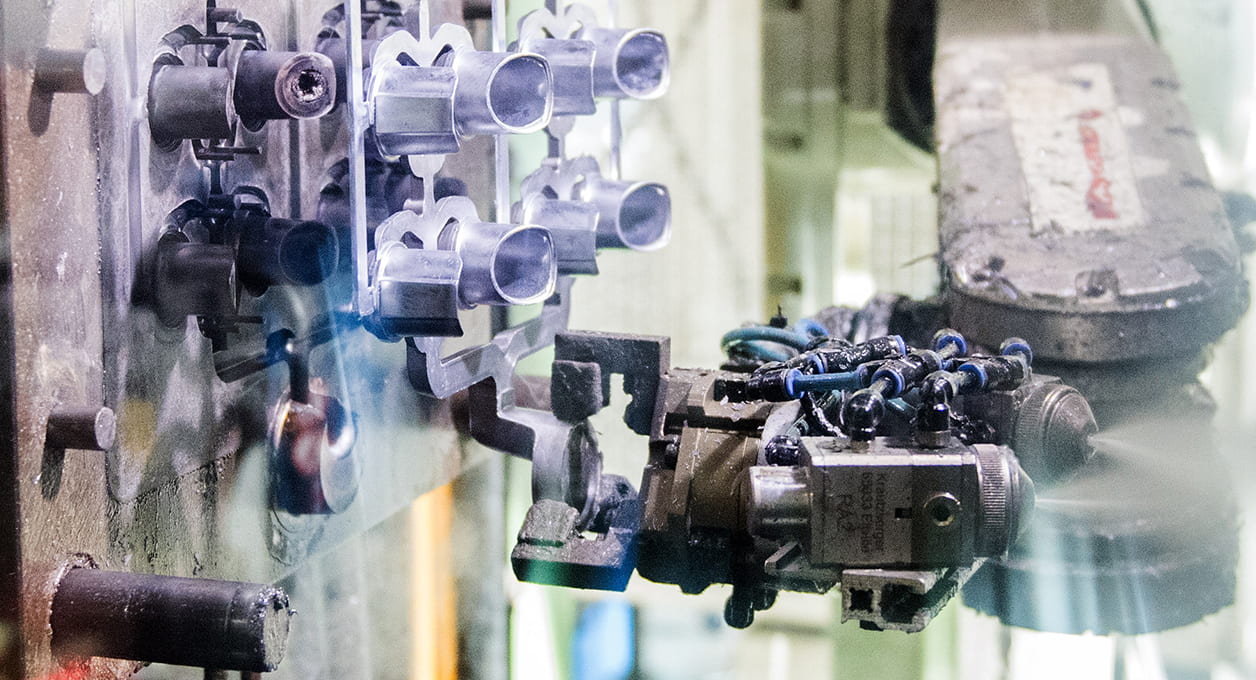

Deburring and cleaning for optimum further processing

To optimally prepare your parts for further processing, we offer various deburring and cleaning processes, including punch deburring, grinding, blasting and the use of washing and cleaning systems.

Our services in precision die casting

From the idea to the ready-to-install component

Discover the precision of die casting with Sander!

Ready to take your projects to the next level? We offer customised precision solutions for your die casting requirements. Contact us today to find out more.

Questions and answers on surface treatment

Surface treatment not only gives die-cast parts an attractive appearance, but also provides additional protection against environmental influences, corrosion and wear. A high-quality surface finish can therefore significantly extend the service life of a product.

Whether electroplating, powder coating, chromating, cathodic dip coating, anodizing, painting or electroless nickel plating: We offer you a wide range of finishing techniques with which the surface of your end product can be decisively optimized.

The choice of the right surface treatment depends on the specific requirements and area of application of the product. Our team of experts will be happy to advise you to find the optimum solution for your product.

Quality is our top priority. We use state-of-the-art technology and meticulous quality controls to ensure that every surface meets our high standards.

We attach great importance to technical cleanliness, especially in the automotive and electrical industries, where low residual contamination is essential. To this end, the company uses its own washing systems to fine-clean and cleanly package products according to customer requirements.

For requirements where the technical cleanliness must be below 500 micrometers, we work together with competent partners. These partners offer parts packaging in a clean room and have a residual dirt laboratory to ensure the cleanliness of the products until they are delivered to the customer.