Aluminium die casting

Excellent quality, homogeneous surfaces and environmentally friendly processes: You too can rely on our just-in-time production.

Aluminium die casting: Filigree products with a homogeneous surface

In aluminium die casting, we press liquid metal under high pressure into preheated steel moulds. This enables the production of thin-walled and delicate products with a homogeneous surface. Our expertise ranges from the processing of common alloys to the production of cast parts with different weights, specialising in medium and large production series. We are able to manufacture components from 2g to 2kg efficiently and to a high standard of quality.

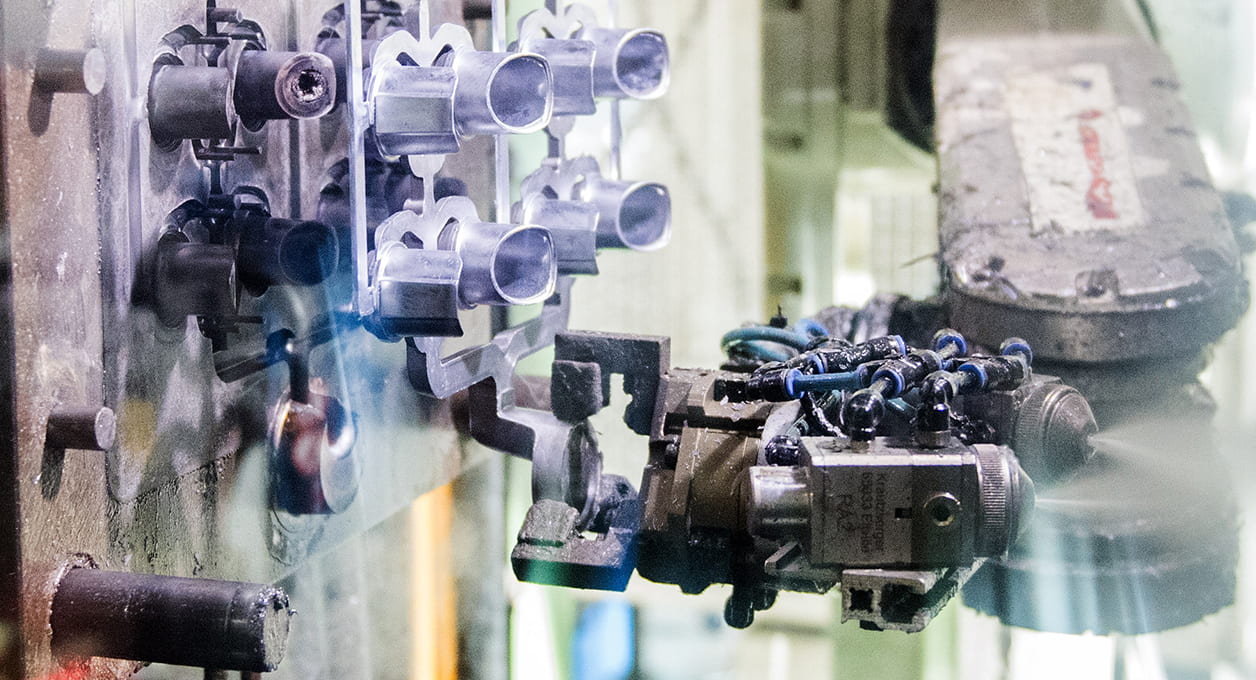

Throughout the entire process, we rely on state-of-the-art technologies and process-monitored aluminium cold chamber machines. This enables us to ensure consistently high quality even with large quantities.

Why you should rely on our expertise in aluminium die casting

- High-precision production for the finest structures and details

- Use in areas with high requirements such as strength, thermal stress and corrosion protection

- Environmentally friendly and recyclable cast aluminium alloys

Our services in precision die casting

From the idea to the ready-to-install component

Discover the precision of die casting with Sander!

Ready to take your projects to the next level? We offer customised precision solutions for your die casting requirements. Contact us today to find out more.

Questions and answers about our aluminium die casting services

Aluminium die casting enables the manufacture of products with high precision and attention to detail. The use of molten metal means that even the finest structures and thin-walled products can be manufactured.

Our die casting process begins with melting the metal in a furnace, followed by precise dosing and pressing under high pressure in a specially developed steel mould. This process allows us to accurately reproduce even the finest details and create complex shapes. Our method offers numerous advantages, including the production of thin-walled and intricate products with a homogeneous surface, narrow tolerance ranges, short throughput times, less material waste and significant cost savings.

Aluminium die cast components are used in numerous areas where high strength, thermal stress, conductivity, electromagnetic incompatibility, corrosion protection and low weight are required.

For aluminium die casting, we rely on process-monitored aluminium cold chamber machines and state-of-the-art technologies. Automation enables us to guarantee consistent quality even with high quantities.

We process all common aluminium casting alloys. All of the alloys we use are also recyclable and environmentally friendly. When recycling, we pay attention to the highest quality and check the alloys regularly.

In addition to the use of recyclable aluminium casting alloys, we rely on environmentally friendly processes and technologies. A particular focus here is on the reuse of sprues, which are melted down and reused in-house, thus eliminating transport routes and saving CO2.

Our machinery consists of aluminium cold chamber machines with a clamping force of 1000 to 6500 kN. Most of these are automated with industrial robots, which ensures consistently high quality even for large quantities. We can produce parts weighing from 2 g to 2000 g.

Our range includes all common alloys as well as special alloys, which are available for download in our alloy table. All materials used are recyclable and environmentally friendly, which is particularly advantageous for medium and large production runs.